When it comes to IIOT (Industrial Internet of Things) and the fourth industrial revolution, data has become exponentially more important to the way we automate machines and processes within a production plant. There are many different types of data, with the most common being process data. Depending on the device or sensor, process data may be as simple as the status of discrete inputs or outputs but can be as complex as the data coming from radio frequency identification (RFID) data carriers (tags). Nevertheless, process data has been there since the beginning of the third industrial revolution and the beginning of the use of programmable logic controllers for machine or process control.

With new advances in technology, sensors used for machine control are becoming smarter, smaller, more capable, and more affordable. This enables manufacturers of those devices to include additional data essential for IIOT and Industry 4.0 applications. The latest type of data manufacturers are outputting from their devices is known as condition monitoring data.

Today, smart devices can replace an entire system by having all of the hardware necessary to collect and process data, thus outputting relative information directly to the PLC or machine controller needed to monitor the condition of assets without the use of specialized hardware and software, and eliminating the need for costly service contracts and being tied to one specific vendor.

A photo-electric laser distance sensor with condition monitoring has the capability to provide more than distance measurements, including vibration detection. Vibration can be associated with loose mechanical mounting of the sensor or possible mechanical issues with the machine that the sensor is mounted. That same laser distance sensor can also provide you with inclination angle measurement to help with the installation of the sensor or help detect when there’s a problem, such as when someone or something bumps the sensor out of alignment. What about ambient data, such as humidity? This could help detect or monitor for moisture ingress. Ambient pressure? It can be used to monitor the performance of fans or the condition of the filter elements on electrical enclosures.

Having access to condition monitoring data can help OEMs improve sensing capabilities of their machines, differentiating themselves from their competition. It can also help end users by providing them with real time monitoring of their assets; improving overall equipment efficiency and better predicting and, thereby, eliminating unscheduled and costly machine downtime. These are just a few examples of the possibilities, and as market needs change, manufacturers of these devices can adapt to the market needs with new and improved functions, all thanks to smart device architecture.

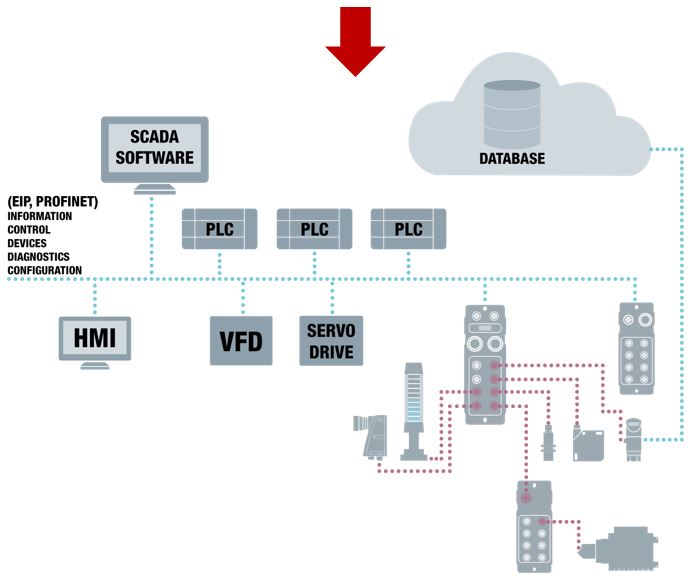

Integrating smart devices to your control architecture

The most robust, cost effective, and reliable way of collecting this data is via the IO-Link communication protocol; the first internationally accepted open, vendor neutral, industrial bi-directional communications protocol that complies with IEC61131-9 standards. From there, this information can be directly passed to your machine controller, such as PLC, via fieldbus communication protocols, such as EtherNET/Ip, ProfiNET or EtherCAT, and to your SCADA / GUI applications via OPC/UA or JSON. There are also instances where wireless communications are used for special applications where devices are placed in hard to reach places using Bluetooth or WLAN.

In the fast paced ever changing world of industrial automation, condition monitoring data collection is increasingly more important. This data can be used in predictive maintenance measures to prevent costly and unscheduled downtime by monitoring vibration, inclination, and ambient data to help you stay ahead of the game.