In a previous post, I talked about receptacles for automation equipment. But there are many different types of mounting when it comes to receptacles. When picking a mounting type, it is based on preference. Each type of mounting has its good points. Depending on what else is inside the cabinet, might sway which mounting is preferred.

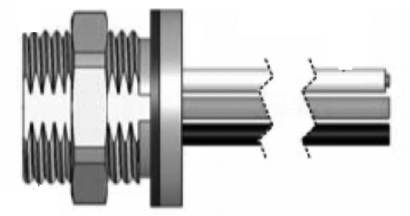

A popular mounting is front mounting. Front mounting comes into the panel from the outside of the control cabinet and is secured with lock (jamming) nut on the inside of the cabinet and sealed with an o-ring on the outside of the cabinet (figure to the right). The o-ring with the lock nut gives the receptacle a tight seal to keep out dust and moisture. It is one of the easier receptacles to replace since it is installed from the outside of the cabinet.

A popular mounting is front mounting. Front mounting comes into the panel from the outside of the control cabinet and is secured with lock (jamming) nut on the inside of the cabinet and sealed with an o-ring on the outside of the cabinet (figure to the right). The o-ring with the lock nut gives the receptacle a tight seal to keep out dust and moisture. It is one of the easier receptacles to replace since it is installed from the outside of the cabinet.

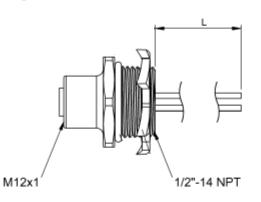

Another mounting type is back mounting. With a back mounting, the threads are on the connector part of the receptacle. Back mounting is the opposite of the front mounting with the o –ring and jamming nut on the outside of the cabinet. A back mounting receptacle takes some preplanning. The receptacle should go into the control cabinet first to make sure there is room for the other components in the cabinet like a power source, PLC or terminals. If the receptacle needs replaced, then it might require some of the components in the cabinet to be removed to have enough room to remove the receptacle.

Another mounting type is back mounting. With a back mounting, the threads are on the connector part of the receptacle. Back mounting is the opposite of the front mounting with the o –ring and jamming nut on the outside of the cabinet. A back mounting receptacle takes some preplanning. The receptacle should go into the control cabinet first to make sure there is room for the other components in the cabinet like a power source, PLC or terminals. If the receptacle needs replaced, then it might require some of the components in the cabinet to be removed to have enough room to remove the receptacle.

Continue reading “Back to the Basics on Receptacles – Part 2”