In the first blog on level detection we discussed containers and single point and continuous level sensing. In this edition we will discuss invasive and non-invasive sensing methods and which sensing technologies apply to each version. Keep in mind that when we are talking about level detection the media can be a liquid, semi-solid or solid with each presenting their own challenges.

Invasive or direct level sensing involves the sensing device being in direct contact to the media being sensed. This means that the container walls or any piping must be violated leading to issue number one – leakage. In some industries such as semiconductor and medical the sensing device cannot contact the media due to the possibility of contamination.

Invasive or direct level sensing involves the sensing device being in direct contact to the media being sensed. This means that the container walls or any piping must be violated leading to issue number one – leakage. In some industries such as semiconductor and medical the sensing device cannot contact the media due to the possibility of contamination.

The direct mounting method could simplify sensor selection and setup since the sensor only has to sense the medium or target material properties. Nonetheless, this approach imposes certain drawbacks, such as costs for mounting and sealing the sensor as well as the need to consider the material compatibility between the sensor and the medium. Corrosive acids, for example, might require a more expensive exotic housing material.

The direct mounting method could simplify sensor selection and setup since the sensor only has to sense the medium or target material properties. Nonetheless, this approach imposes certain drawbacks, such as costs for mounting and sealing the sensor as well as the need to consider the material compatibility between the sensor and the medium. Corrosive acids, for example, might require a more expensive exotic housing material.

Invasive sensing technologies that would solve level sensing applications include capacitive, linear transducers, hydrostatic with pressure sensors.

In many cases the preferred approach is indirectly or non-invasively mounting the sensor on the outside of the container. This sensing method requires the sensor to “see” through the container walls or by looking down at the media from above the container through an opening in the top of the container. The advantages for this approach are easier mounting, lower cost and easier to field retro-fit. The container wall does not have to be penetrated, which leaves the level sensor flexible and interchangeable in the application. Avoiding direct contact with the target material also reduces the chances of product contamination, leaks, and other sources of risk to personnel and the environment.

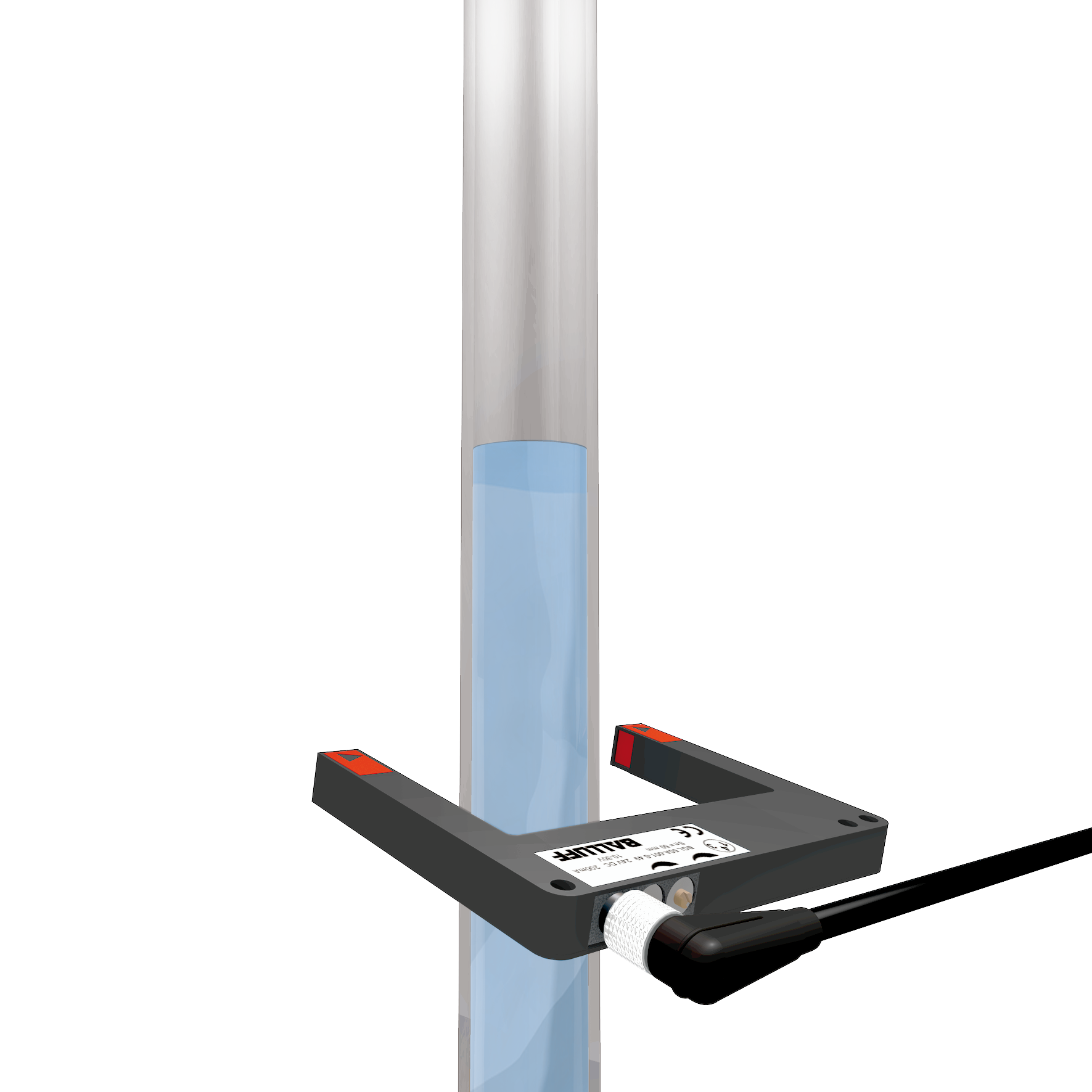

In some cases a sight glass is used which is mounted in the wall of the tank and as the liquid media rises it flows into the sight glass. When using a sight glass a fork style photoelectric sensor can be used or a capacitive sensor can be strapped to the sight glass.

In some cases a sight glass is used which is mounted in the wall of the tank and as the liquid media rises it flows into the sight glass. When using a sight glass a fork style photoelectric sensor can be used or a capacitive sensor can be strapped to the sight glass.

The media also has relevance in the sensor selection process. Medical and semiconductor applications involve mostly water-based reagents, process fluids, acids, as well as different bodily fluids. Fortunately, high conductivity levels and therefore high relative dielectric constants are common characteristics among all these liquids. This is why the primary advantages of capacitive sensors lie in non-invasive liquid level detection, namely by creating a large measurement delta between the low dielectric container and the target material with high dielectric properties. At the same time, highly conductivity liquids could impose a threat to the application. This is because smaller physical amounts of material have a larger impact on the capacitive sensor with increasing conductivity values, increasing the risk of false triggering on foam or adherence to the inside or outside wall.

Non-invasive or indirect level sensing technologies include photoelectrics, capacitive, linear transducers with a sight glass and ultrasonics.

For more information visit www.balluff.com.

Non-metallic containers may provide the ability for the sensors look down to see the media with the same technologies mentioned above or by sensing through the walls of the container. Capacitive sensors can sense through the walls of a container up to 4mm thick with standard technology or up to 10mm thick using a hybrid capacitive technology offered by Balluff when detecting water based conductive materials. If the container is clear or translucent we have photoelectric sensors that can look through the side walls to detect the media.

Non-metallic containers may provide the ability for the sensors look down to see the media with the same technologies mentioned above or by sensing through the walls of the container. Capacitive sensors can sense through the walls of a container up to 4mm thick with standard technology or up to 10mm thick using a hybrid capacitive technology offered by Balluff when detecting water based conductive materials. If the container is clear or translucent we have photoelectric sensors that can look through the side walls to detect the media.