Digital work instructions are becoming a game-changer in the increasingly fast-paced manufacturing world. They offer many benefits that enhance efficiency, reduce errors, and foster collaboration.

The digital advantage

Digital work instructions offer real-time updates, ensuring that all operators can access the latest version, even across various production facilities. This eliminates costly mistakes caused by outdated instructions or checklists.

These instructions are often part of larger workflows or Standard Operating Procedures (SOPs). Digital solutions can enable the seamless initiation of related procedures. For instance, if an operator identifies a machine issue, they can launch a workflow directly from the system for other team members or external workers.

Seamless integration

Digital work instructions integrate with planning systems, providing real-time visibility into expectations. Integrating ERP, MES, or LIMS systems allows data exchange and automated report generation.

Interactive feedback

Digital work instructions facilitate responsive interactions, unlike paper-based ones. When a threshold value is exceeded, the system can immediately alert the operator, who can notify supervisors or promptly follow additional instructions.

Automatic logging

Digital systems automatically record executed procedures, providing invaluable for compliance audits and continuous improvement initiatives.

Visual enhancement

Work instructions are often enhanced with multimedia elements such as images, videos, or 3D models. These visual aids enhance communication and comprehension and often reduce operator errors.

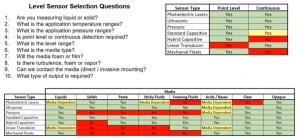

The future of manufacturing: sensor feedback

Sensors provide live data on equipment performance, environmental conditions, and safety parameters. This allows operators to receive immediate feedback for proactive adjustments, timely preventive actions, and “predictive maintenance” by monitoring wear and tear. Predictive maintenance helps schedule maintenance before critical failures occur, minimizing downtime, extending equipment lifespan, and ensuring efficient use of resources.

Additionally, sensors can detect deviations from optimal conditions, enabling operators to promptly address issues and maintain consistent product quality.

In conclusion, digital work instructions streamline processes, foster collaboration, and empower operators. When integrated with sensor feedback, businesses can gain efficiency and accuracy and, for a moment, enjoy that ever-elusive competitive edge in today’s rapidly evolving business environment.