In the last post about the Basics of Automation, we discussed how objects can be detected, collected and positioned with the help of sensors. Now, let’s take a closer look at how non-contact measurement—both linear and rotary—works to measure distance, travel, angle, and pressure.

Measuring travel, distance, position, angle and pressure are common tasks in automation. The measuring principles used are as varied as the different tasks.

Sensor Technologies

- Magnetostrictive enables simultaneous measurement of multiple positions and can be used in challenging environments.

- Magnet coded enables the highest accuracy and real-time measurement.

- Inductive is used for integration in extremely tight spaces and is suitable for short distances.

- Photoelectric features flexible range and is unaffected by the color or surface properties of the target object.

Different Sensors for Different Applications

Distance measurement

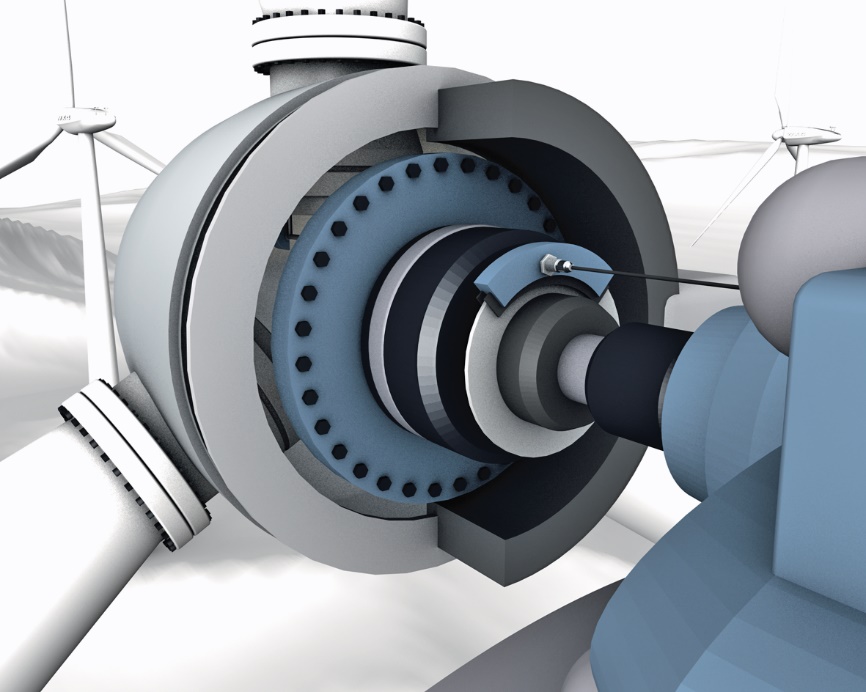

Disc brakes are used at various locations

Disc brakes are used at various locations

in wind power plants. With their durability and precise measurement, inductive distance sensors monitor these brake discs continuously and provide a timely warning if the brake linings need to be changed.

In winding and unwinding equipment, a photoelectric sensor continuously measures the increasing or decreasing roll diameter. This means the rolls can be changed with minimal stoppages.

Linear position measurement

Workpieces are precisely positioned on the slide of a linear axis. This allows minimal loss of production time while ensuring quality. Magnetic encoders installed along the linear axis report the actual slide position to the controller (PLC) continuously and in real time — even when the slide is moving at a speed of up to 10 m/s.

Workpieces are precisely positioned on the slide of a linear axis. This allows minimal loss of production time while ensuring quality. Magnetic encoders installed along the linear axis report the actual slide position to the controller (PLC) continuously and in real time — even when the slide is moving at a speed of up to 10 m/s.

In a machine tool the clamping state of a spindle must be continuously monitored during machining. This improves results on the workpiece and increases the reliability of the overall system. Inductive positioning systems provide continuous feedback to the controller: whether the spindle is unclamped, clamped with a tool or clamped without a tool.

Rotational position measurement

Workpieces such as a metal plate are printed, engraved or cut on a cut/print machine. This demands special accuracy in positioning it on the machine. Magnetic encoders on both rotating axes of the machine measure the position of the workpiece and ensure an even feed rate.

Workpieces such as a metal plate are printed, engraved or cut on a cut/print machine. This demands special accuracy in positioning it on the machine. Magnetic encoders on both rotating axes of the machine measure the position of the workpiece and ensure an even feed rate.

In a parabolic trough system,

sunlight is concentrated on parabolic troughs using parabolic mirrors allowing the heat energy to be stored. To achieve the optimal energy efficiency, the position of the parabolic mirror must be guided to match the sun’s path. Inclination sensors report the actual position of the parabolic mirror to the controller, which then adjusts as needed.

Pressure and Level Measurement

Consistently high surface quality of the machined workpiece must be ensured in a machine tool. This requires continuous monitoring of the coolant feed system pressure. Pressure sensors can reliably monitor the pressure and shut down the machine within a few milliseconds when the defined pressure range is violated.

Consistently high surface quality of the machined workpiece must be ensured in a machine tool. This requires continuous monitoring of the coolant feed system pressure. Pressure sensors can reliably monitor the pressure and shut down the machine within a few milliseconds when the defined pressure range is violated.

In many tanks and vats, the fill height of the liquid must be continually measured. This is accomplished using ultrasonic sensors, which note levels regardless of color, transparency or surface composition of the medium. These sensors detect objects made of virtually any material (even sound-absorbing) including liquids, granulates and powders.

In many tanks and vats, the fill height of the liquid must be continually measured. This is accomplished using ultrasonic sensors, which note levels regardless of color, transparency or surface composition of the medium. These sensors detect objects made of virtually any material (even sound-absorbing) including liquids, granulates and powders.

Stay tuned for future posts that will cover the essentials of automation. To learn more about the Basics of Automation in the meantime, visit www.balluff.com.