When we think about inductive sensors we automatically refer to discrete output offerings that detect the presence of ferrous materials. This can be a production part or an integrated part of the machine to simply determine position. Inductive sensors have been around for a long time, and there will always be a need for them in automated assembly lines, weld cells and stamping presses.

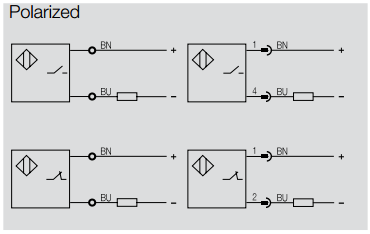

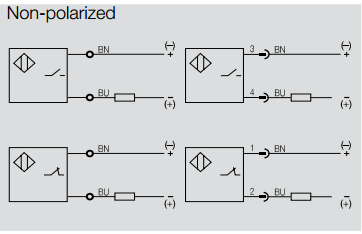

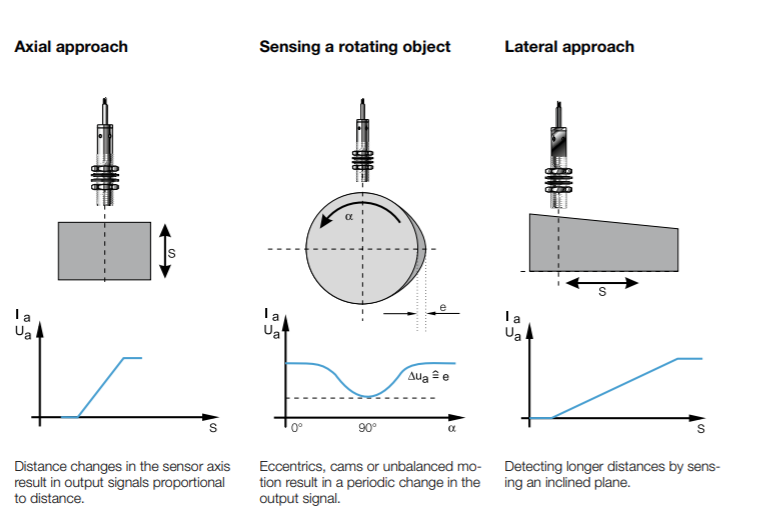

We often come across applications where we need an analog output at short range that needs to detect ferrous materials. This is an ideal application for an analog inductive proximity sensor that can offer an analog voltage or analog current output. This can reliably measure or error proof different product features such as varying shapes and sizes. Analog inductive sensors are pure analog devices that maintain a very good resolution with a high repeat accuracy. Similar to standard inductive sensors, they deal very well with vibration, commonly found in robust applications. Analog inductive proximity sensors are also offered in many form factors from M12-M30 tubular housings, rectangular block style and flat housings. They can also be selected to have flush or non-flush mounting features to accommodate specific operating distances needed in various applications.

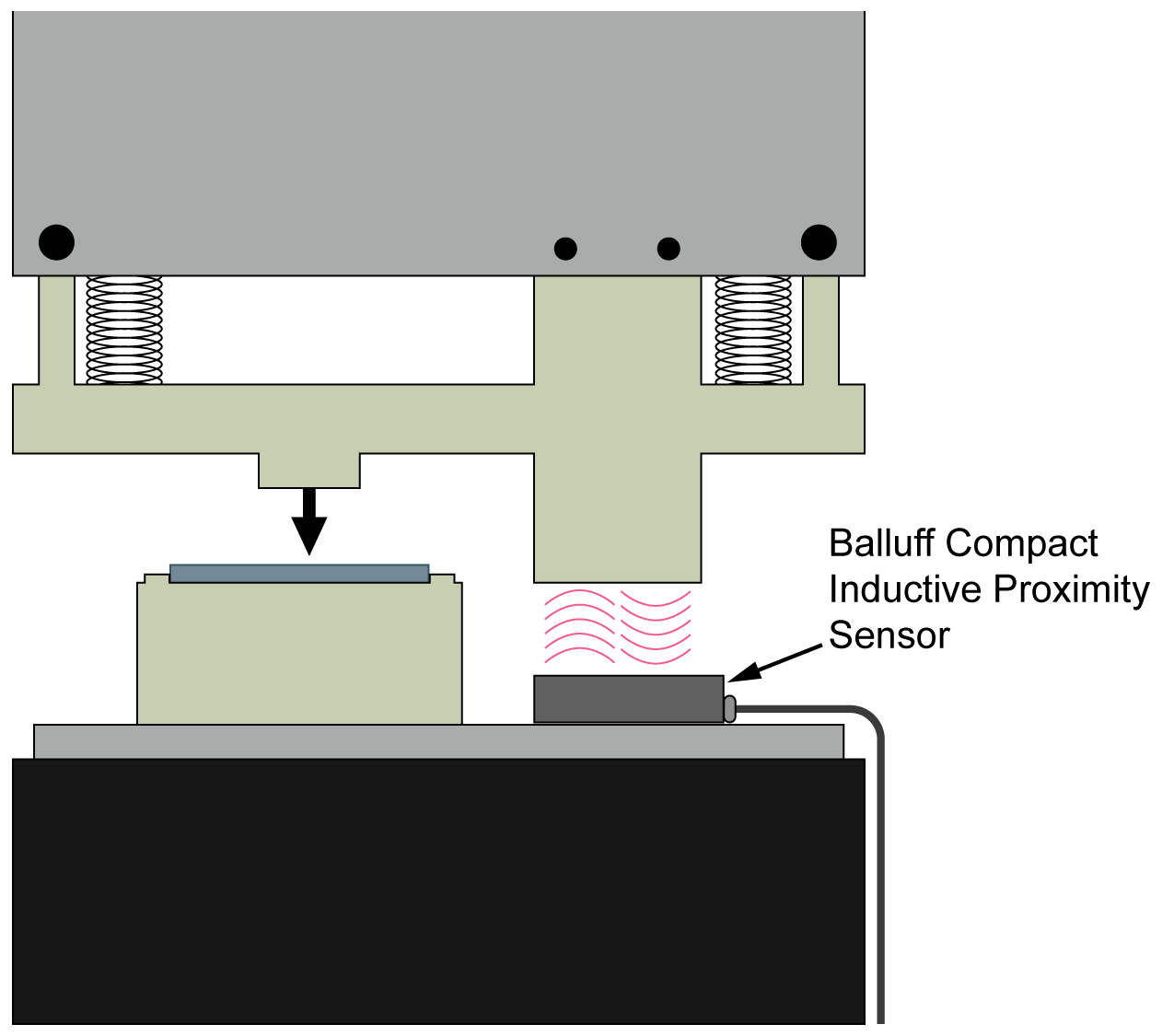

Application Examples:

For more specific information on analog inductive sensors visit www.balluff.com.

When selecting the proper Inductive sensor it is very important to understand the type of application environment the sensor will be installed in. In

When selecting the proper Inductive sensor it is very important to understand the type of application environment the sensor will be installed in. In  Features:

Features: