It goes without saying that food safety is an extremely important aspect of the food and beverage industry. While manufacturers would naturally take precautions to ensure their food products are safe to consume, they are required to follow a set of rigid guidelines and standards to ensure the safety of the foodstuffs to prevent contamination.

To determine which rating, standards or certifications are required for a particular food and beverage segment, you must first consider the type of food contact zone and whether it is an open or closed process.

To determine which rating, standards or certifications are required for a particular food and beverage segment, you must first consider the type of food contact zone and whether it is an open or closed process.

Food Contact Zones

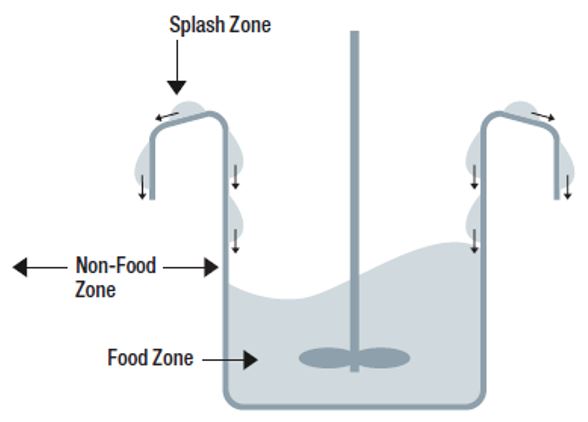

The food contact zone is determined by the potential contamination that can occur based on the production equipment’s exposure to food and its byproducts.

- Food Zone: an area intended to be exposed to direct contact with food or surfaces where food or other substances may contact and then flow, drain or drain back onto food or food contact surfaces.

- Splash Zone: an area that is routinely exposed to indirect food contact due to splashes and spills. These areas are not intended for contact with consumable food.

- Nonfood Zone: An area that is not exposed to food or splashes but will likely be exposed to minor dirt and debris.

Open and Closed Production

In the food and beverage industry, it is also important to discuss whether the manufacturing process is open or closed. The distinction between the two plays a significant role in determining machine cleaning requirements.

- Closed Process: A manufacturing operation in which the food product never comes in contact with the environment. All food contact zones are sealed such as the inner surfaces of tanks, pipelines, valves, pumps and sensors.

- Open Process: A manufacturing operation in which food does have contact with the environment outside of the machine. This requires a hygienic design of the process environment, as well as the surfaces of the apparatus and components.

Required ratings, standards and certifications

Once you know the food zone and whether the production is open or closed, it becomes simple to determine which ratings, standards or certifications are required of the machinery and apparatus in the food and beverage manufacturing process.

- Food Contact Zone — Hygienic

- IP69K – tested to be protected from high pressure steam cleaning per DIN40050 part 9

- FDA – made of FDA approved materials, most often 316L stainless steel

- 3-A – certified sanitary and hygienic equipment materials and design in the US

- EHEDG – certified sanitary and hygienic equipment materials and design in Europe

- Food Splash Zone — Washdown

- IP69K – tested to be protected from high pressure steam cleaning per DIN40050 part 9

- ECOLAB – surfaces tested to be protected from cleaning and disinfecting agents

- Nonfood Zone — Factory Automation

- IP67 – rated for water immersion up to a meter deep for half an hour

- IP65 – rated as dust tight and protected against water projected from a nozzle

For more information on the requirements of the food and beverage industry, visit www.balluff.com.