The requirement for miniature optical sensors to meet the demands of medical and semiconductor automation equipment often exceeds the capabilities of standard self-contained optical sensors. In some cases, other industry application requirements can be best solved by these same miniature optical sensors with advanced capabilities. So, what do these optical sensors offer that makes them so much better?

The requirement for miniature optical sensors to meet the demands of medical and semiconductor automation equipment often exceeds the capabilities of standard self-contained optical sensors. In some cases, other industry application requirements can be best solved by these same miniature optical sensors with advanced capabilities. So, what do these optical sensors offer that makes them so much better?

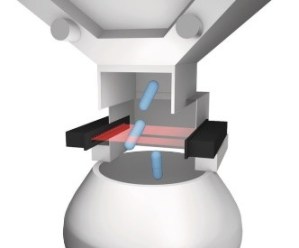

Let’s begin with some of the applications that require these capabilities: medical applications, such as lab-on-a-chip microfluidics, liquid presence or level in drip chambers or pipettes, turbidity, drop detection, and micro or macro bubble detection, to name a few. Semicon applications include wafer presence on end-effectors, wafer mapping, wafer centering, and wafer presence in transfer chambers. Other applications that benefit from these sensors include packaging pharmaceuticals, detecting extremely small parts, and spray detection. In addition, these sensors are frequently used in customer-specific designs because they can be customized for specific applications.

These sensors require an amplifier which sometimes is not popular with design engineers. They are associated with additional cost and extra work during installation; however, the remote amplifier offers real advantages. The optical function is separate from the control unit which allows it to be incorporated into an extremely tiny sensor head. Since the LEDs are mounted in the sensor heads, we now have a small wired connection back to the amplifier. Unlike fiber optics, this wired connection to the emitting LED and receiver allows for very minimal or no bending radius because of the cable in use.

These sensors require an amplifier which sometimes is not popular with design engineers. They are associated with additional cost and extra work during installation; however, the remote amplifier offers real advantages. The optical function is separate from the control unit which allows it to be incorporated into an extremely tiny sensor head. Since the LEDs are mounted in the sensor heads, we now have a small wired connection back to the amplifier. Unlike fiber optics, this wired connection to the emitting LED and receiver allows for very minimal or no bending radius because of the cable in use.

Features

The new generation of amplifiers offers tremendous flexibility with advanced features, including:

-

- OLED display

- Intuitive menu structure

- LEDs for status, communication, and warnings

- Teaching/Parametrization

- Single-point, two-point, window, dynamic, and tracking operating modes

- Multiple teach modes: direct, dynamic, external, automatic and I/O-Link

- Selectable power modes

- Selectable outputs

- Selectable speed settings

- Auto-sync up to 8 amplifiers

- Configurable delays and hysteresis

- Compatible with existing all sensor heads

- OLED display

The sensor heads or optical heads come in a wide variety of housings, including the ability to customize them to meet specific requirements. And they are available in small precision LEDs, photodiodes, phototransistors, and complete laser modules according to a patented manufacturing process. Due to the high optical quality, additional lenses or apertures are no longer necessary.

A multitude of special characteristics completely differentiates these sensors from the products made by standard optical sensor manufacturers. The range of products includes extraordinary miniature optical sensors as standard products, optimally adapted customized solutions, and precision optoelectronic components, such as LEDs, photodiodes, and laser modules. High optical quality, and unique modular designs, in connection with the greatest possible manufacturing flexibility, guarantee solutions that are exactly adapted to the respective problems and needs of the users.

A multitude of special characteristics completely differentiates these sensors from the products made by standard optical sensor manufacturers. The range of products includes extraordinary miniature optical sensors as standard products, optimally adapted customized solutions, and precision optoelectronic components, such as LEDs, photodiodes, and laser modules. High optical quality, and unique modular designs, in connection with the greatest possible manufacturing flexibility, guarantee solutions that are exactly adapted to the respective problems and needs of the users.