Continuous control of process media significantly contributes to the reliability of industrial production. More and more process technology is involved in industrial manufacturing. Besides pressure and level sensors, temperature sensors are also needed to monitor and control these media. Although new machine designs are often optimized in terms of energy efficiency, heat is added to the production equipment.

Process stability

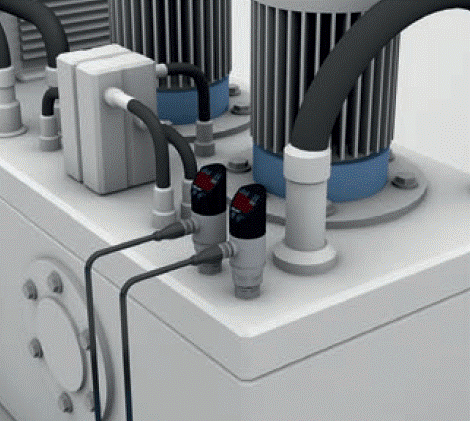

To achieve a defined and stable temperature level (in many cases only slightly above the environmental temperature) the added heat dissipation of the production process constantly must be managed. Typically a coolant liquid or hydraulic fluid is cycling through the areas of the production equipment, which tend to heat up. It then runs to a heat exchanger system which cools down the liquid to a defined value. Some applications even require a defined viscosity of the liquids in use. Often the media viscosity depends on its temperature. Historically classic cylindrical housing temperature probes have been applied for temperature measurement. The values are transferred by cables to a PLC. For factory automation applications, housings with integrated display and an adjustable switching point (via pushbutton parametrization) have become more and more popular.

Many housing styles now also include a digital display so in addition to the sensor transmitting temperature values via cable to the control system, they provide a visual monitoring functionality for the machine/plant operator.

Monitoring of industrial processes

Monitoring of industrial processes has become more and more relevant. With increasing digitalization in manufacturing, the demand of transparent visualization of the production constantly grows.